Safety Tips Workers Must Follow When Dealing With Chemicals

Chemical manufacturing processes produce many of the products that make modern living possible. However, they often require large volumes of potentially dangerous materials that workers must know how to handle.

A lack of preparation can result in workplace accidents and increased hazards that put yourself and others at risk. Here are the most essential safety tips workers must follow when dealing with chemicals.

Follow established procedures

Those who work with chemicals in industrial manufacturing must follow regulatory guidelines to ensure they stay safe during operations. Learning how to handle chemicals safely is essential for anyone who works with or near hazardous materials.

Chemical vats and containers should remain sealed when not in use. Reagents should get appropriately marked so that workers know what’s in them and the dangers they pose. Employees should receive ongoing training and education to ensure they understand the latest industry best practices.

Wear the required PPE

Employees must protect themselves in case of exposure to chemical spills, splashes, or vapors. That’s why employers generally require them to wear PPE at all times. Equipment should provide adequate protection against ingestion, inhalation, and skin contact to minimize worker risk.

Dangers posed by fire, electrocution, and chemical contamination are the most significant reasons chemical plants require FR clothes. Exposure to these hazards can lead to poor health, injury, or even death if not dealt with properly.

Pay attention to labels and the SDS

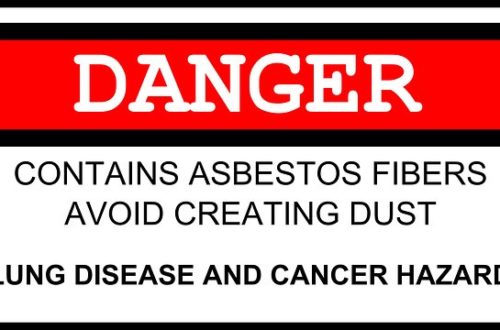

Industrial chemicals and solvents should get stored in properly labeled containers so workers don’t accidentally mix them up. Labels are essential for reducing workplace accidents and maintaining OSHA compliance.

Safety data sheets (SDS) provide important information about the chemicals, their dangers to individual health, and how to handle them. Paying attention to the details during product use, storage, or transportation will reduce the likelihood of exposure.

Being prepared will help limit unwanted exposure

Industrial manufacturing plants that work with chemicals must have procedures in place to reduce the likelihood of exposure to workers and anyone else in the vicinity.

There are many safety tips workers must follow when dealing with chemicals. Learning standard procedures, wearing required protective equipment, and paying attention to safety information will help workers reduce the likelihood of an accident.

Would you like to receive similar articles by email?